Analysis of Advantages of Moving Box Hydraulic Station Compared to Traditional Mechanical Transmission

Release Time :

2024-07-03

In the modern industrial field, the transmission system is an indispensable and important component of mechanical equipment. With the continuous advancement of technology, hydraulic transmission, as an advanced transmission method, has gradually been widely applied in various fields. Especially in box shifting operations, hydraulic stations for box shifting have shown significant advantages compared to traditional mechanical transmissions. This article will compare the hydraulic transfer station with traditional mechanical transmission and explore its advantages.

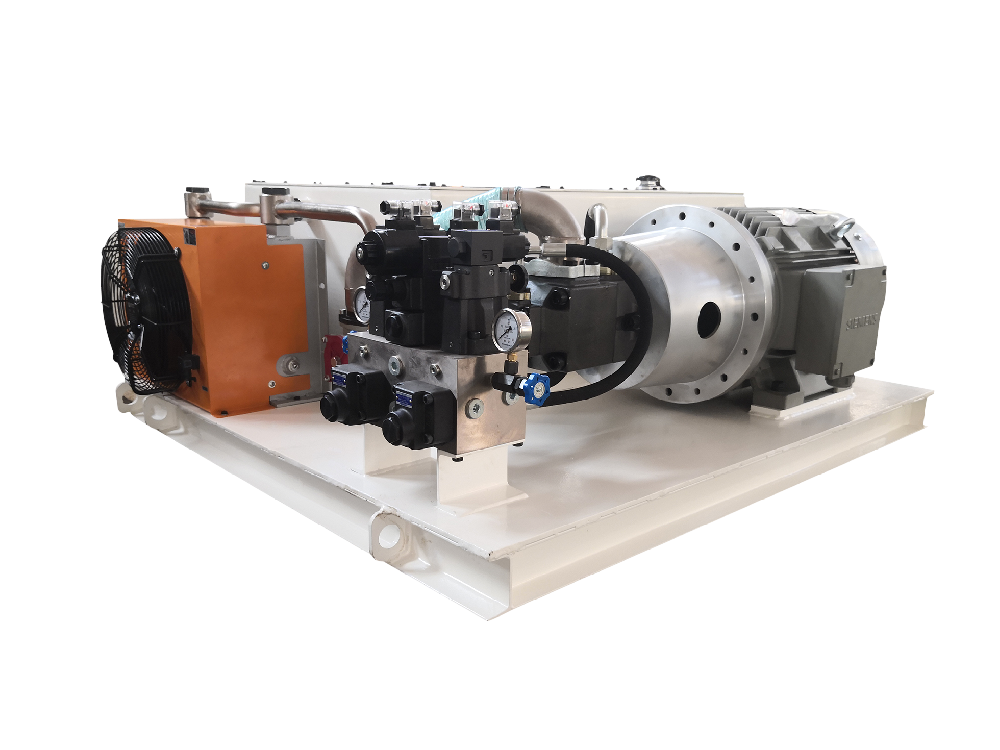

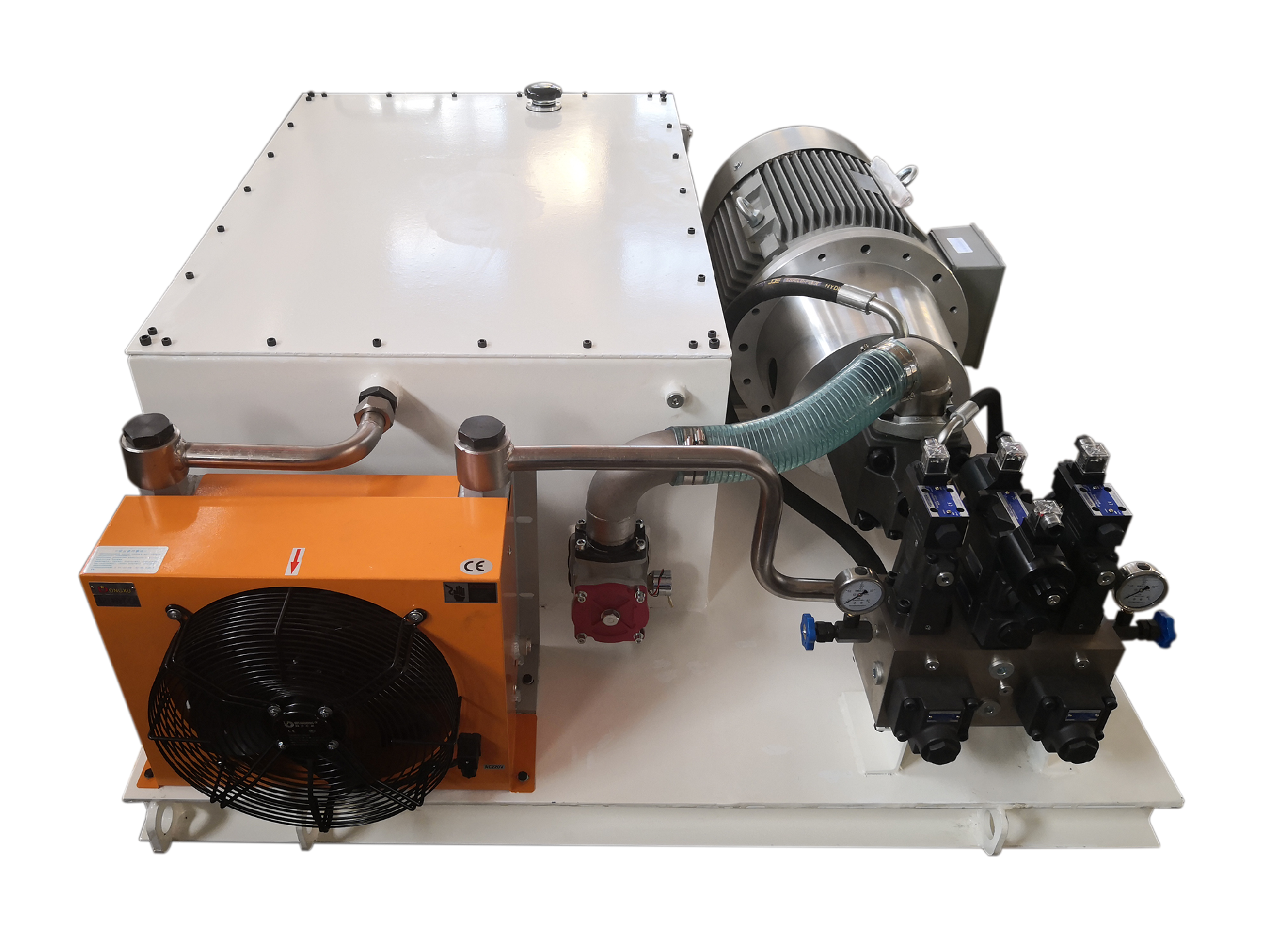

1、 The basic principle and characteristics of moving box hydraulic station

The shifting hydraulic station is a transmission method that uses hydraulic oil as the working medium and utilizes the pressure energy of the liquid for energy conversion, transmission, and control. It mainly consists of hydraulic pumps, hydraulic cylinders, hydraulic control valves, oil tanks, pipelines, etc., and can achieve fast, stable, and reliable displacement and positioning. The hydraulic station for moving boxes has the characteristics of small volume, light weight, high power density, fast response speed, and high control accuracy.

2、 Comparison between Moving Box Hydraulic Station and Traditional Mechanical Transmission

1. Transmission efficiency and power density

The transfer box hydraulic station uses liquid as the transmission medium, which has higher transmission efficiency and power density. In contrast, traditional mechanical transmissions have lower transmission efficiency and limited power density due to factors such as friction and wear. Therefore, under the same power, the shifting hydraulic station can provide greater thrust and faster speed to meet higher operational requirements.

2. Response speed and smoothness

The shifting hydraulic station adopts liquid transmission, which can achieve fast and stable displacement and positioning. The hydraulic system has a fast response speed and can quickly respond to control signals, achieving precise displacement control. At the same time, hydraulic transmission has good buffering performance, which can reduce impact and vibration, and improve operational stability. However, traditional mechanical transmissions have relatively poor response speed and stability, making it difficult to meet the requirements of high-precision operations.

3. Control accuracy and flexibility

The transfer box hydraulic station adopts advanced hydraulic control technology, which can achieve high-precision displacement and positioning control. By adjusting the opening and pressure of the hydraulic control valve, the stretching speed and position of the hydraulic cylinder can be precisely controlled. In addition, hydraulic transmission also has high flexibility and can adjust transmission parameters and modes according to operational requirements. However, traditional mechanical transmissions have relatively poor control accuracy and flexibility, making it difficult to meet complex and ever-changing operational requirements.

4. Safety and reliability

The hydraulic station for moving boxes has high safety and reliability. Each component in the hydraulic system has been carefully designed and manufactured to withstand large loads and impacts. At the same time, the hydraulic system is also equipped with various safety protection devices, such as overload protection, pressure protection, etc., to ensure that the power source can be quickly cut off in emergency situations, ensuring the safety of personnel and equipment. However, traditional mechanical transmissions have relatively poor safety and are prone to malfunctions and accidents.

3、 Conclusion

In summary, compared to traditional mechanical transmission, the transfer box hydraulic station has shown significant advantages in transmission efficiency, power density, response speed, smoothness, control accuracy, flexibility, and safety. These advantages enable the hydraulic station for moving boxes to better meet the requirements of high precision, high efficiency, and high safety in box moving operations. Therefore, in the future development, the hydraulic station for moving boxes is expected to be more widely applied and promoted.

RELATED NEWS

2026-01-29

How Do Hydraulic Cylinders Enhance Railway System Safety?

Railway system safety is a critical concern for modern transportation networks, and hydraulic cylinders play an essential role in ensuring reliable and secure railway operations. As key components in various railway applications, hydraulic ···

2026-01-29

How Are Hydraulic Cylinders Adapted for Extreme Metallurgical Conditions?

Hydraulic cylinders play a critical role in metallurgical industries such as steelmaking, aluminum processing, and metal forging. These environments are characterized by extreme temperatures, heavy loads, corrosive media, and continuous hig···

2026-01-22

How Do Hydraulic Cylinders Enhance Railway System Safety?

Railway systems are among the most critical transportation infrastructures worldwide, carrying millions of passengers and vast quantities of freight every day. Ensuring safety, reliability, and operational efficiency is therefore a top prio···

2026-01-22

How Do Our Hydraulic Cylinders Enhance Railway Equipment Reliability?

Railway systems demand extreme reliability. From braking and suspension to door control and maintenance machinery, every component must operate safely under high loads, vibration, and harsh environmental conditions. Among these critical com···

2026-01-15

How Are Hydraulic Cylinders Used in Metallurgical Electric Furnaces?

Metallurgical electric furnaces play a crucial role in modern steelmaking and non-ferrous metal smelting processes. These furnaces operate under extreme conditions, including high temperatures, heavy mechanical loads, and continuous operati···

2026-01-15

How Does Our Hydraulic Cylinder Enhance Metallurgical Electric Furnace Control?

In metallurgical electric furnace systems—such as electric arc furnaces (EAF), submerged arc furnaces, and resistance furnaces—precise mechanical control plays a critical role in ensuring stable operation, energy efficiency, and equipment···

GET YOUR FREE QUOTE

We will contact you within 24 hours. ( WhatsApp/facebook:13665121168)