How do you tell if a cylinder is hydraulic or pneumatic?

Release Time :

2025-02-11

Cylinders

Cylinders, also known as pneumatic actuators or air cylinders, use gas to create force or motion. They function similarly to hydraulic cylinders, but instead of using fluids, they rely on compressed air as a power source.

These cylinders are often used in industries that require fast and efficient motion, such as automation, food processing, and packaging. Cylinders are lightweight, easy to install, and low maintenance, making them a popular choice for many industrial applications. Cylinders come in a variety of sizes and types to suit different application needs.

They are reliable, stable, have high precision and repeatability tolerances, and can operate in extreme temperatures. They are also safe to use and do not require hazardous materials. However, they operate at lower speeds and pressures, and there is also a risk of contamination from the air used to drive them.

What are the characteristics of cylinders?

Pneumatic systems use compressed air instead of fluids to create force. Pneumatic cylinders are generally less expensive, simpler, and safer to operate than hydraulic cylinders. Pneumatic cylinders are often used in vacuum pumps and manufacturing equipment.

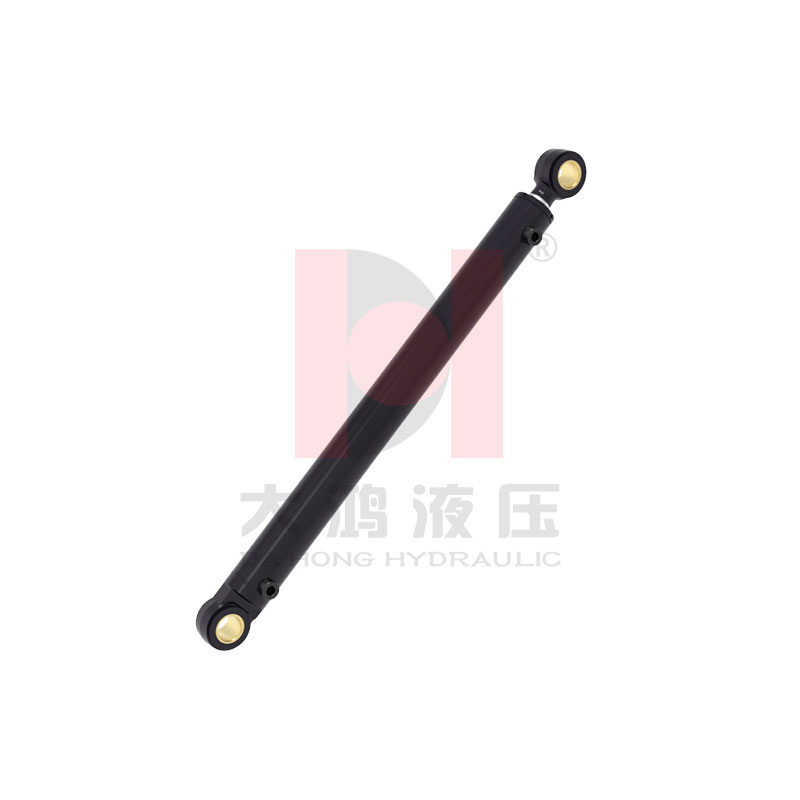

Hydraulic cylinders

Hydraulic cylinders, on the other hand, use hydraulic fluid to create motion. These cylinders are often used in heavy-duty applications, such as construction equipment, mining, and agriculture. Hydraulic cylinders are capable of generating a lot of force and are often used in applications that require lifting or pushing heavy objects.

One advantage of hydraulic cylinders is their ability to maintain force over long distances, which makes them ideal for applications that require sustained force. However, hydraulic cylinders require more maintenance than pneumatic cylinders because they are prone to leaks and require regular fluid changes. In addition, they are heavier and larger compared to pneumatic cylinders.

Other characteristics to consider include the fact that hydraulic systems and the equipment used to power them tend to be larger, more complex, and more expensive than pneumatic systems. This means that maintenance requirements are also more specialized. However, if operated and maintained properly, heavy-duty hydraulic cylinders can do jobs that other equipment cannot.

RELATED NEWS

2026-01-22

How Do Hydraulic Cylinders Enhance Railway System Safety?

Railway systems are among the most critical transportation infrastructures worldwide, carrying millions of passengers and vast quantities of freight every day. Ensuring safety, reliability, and operational efficiency is therefore a top prio···

2026-01-22

How Do Our Hydraulic Cylinders Enhance Railway Equipment Reliability?

Railway systems demand extreme reliability. From braking and suspension to door control and maintenance machinery, every component must operate safely under high loads, vibration, and harsh environmental conditions. Among these critical com···

2026-01-15

How Are Hydraulic Cylinders Used in Metallurgical Electric Furnaces?

Metallurgical electric furnaces play a crucial role in modern steelmaking and non-ferrous metal smelting processes. These furnaces operate under extreme conditions, including high temperatures, heavy mechanical loads, and continuous operati···

2026-01-15

How Does Our Hydraulic Cylinder Enhance Metallurgical Electric Furnace Control?

In metallurgical electric furnace systems—such as electric arc furnaces (EAF), submerged arc furnaces, and resistance furnaces—precise mechanical control plays a critical role in ensuring stable operation, energy efficiency, and equipment···

2026-01-08

What Drives Demand for Welded High-Pressure Cylinders?

Welded high-pressure cylinders play a critical role in the storage and transportation of compressed gases across multiple industries. Unlike seamless cylinders, welded cylinders are manufactured by forming and welding steel components, allo···

2026-01-08

How Do We Ensure Durability in High-Pressure Welded Cylinders?

High-pressure welded cylinders are widely used in industries such as energy, chemical processing, medical gases, and industrial manufacturing. Because these cylinders often operate under extreme internal pressure and harsh environments, dur···

GET YOUR FREE QUOTE

We will contact you within 24 hours. ( WhatsApp/facebook:13665121168)