What are the basics of hydraulic cylinders?

Release Time :

2025-02-11

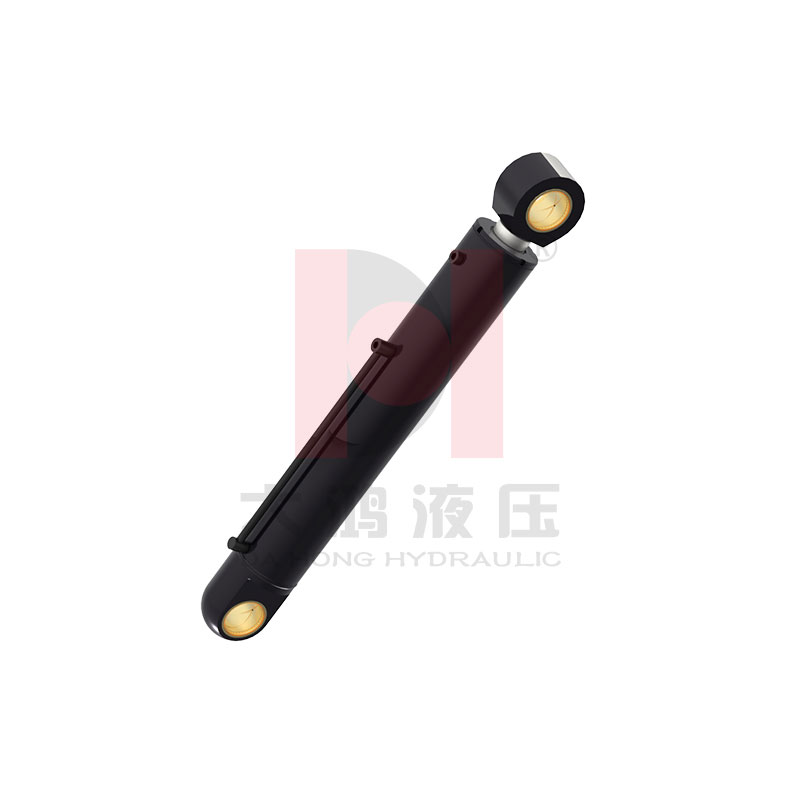

A hydraulic cylinder is a hydraulic actuator that converts hydraulic energy into mechanical energy and performs linear reciprocating motion (or swinging motion). It has a simple structure and reliable operation. When used to achieve reciprocating motion, the reduction device can be omitted, there is no transmission gap, and the motion is smooth, so it is widely used in the hydraulic systems of various machines.

Linear motion

Hydraulic cylinders use high-pressure fluid (oil) to convert pressure into motion/force. The rod assembly moves relative to the tube assembly, driven by the fluid pressure in the tube assembly.

The motion is guided by a pair of linear bearing surfaces that support the piston/rod in the tube hole and the rod in the tube head. A variety of forms of bearing systems are commonly used in cylinder structures, depending on the technical and economic requirements of the application. Factors to consider include:

Operating speed

Side loading

Expected life

Maintenance requirements

Manufacturing cost

Pressure vessel

The high pressure used to produce linear motion must be safely contained within the cylinder tube and connected to the hydraulic system that provides energy input. This pressure is controlled by the joints used in the cylinder tube structure. The pressure joints can be:

Static seals

Permanent joints, such as welded joints

Mechanical assembly

Dynamic seals

Allow sliding motion while continuing to maintain fluid pressure.

RELATED NEWS

2026-01-22

How Do Hydraulic Cylinders Enhance Railway System Safety?

Railway systems are among the most critical transportation infrastructures worldwide, carrying millions of passengers and vast quantities of freight every day. Ensuring safety, reliability, and operational efficiency is therefore a top prio···

2026-01-22

How Do Our Hydraulic Cylinders Enhance Railway Equipment Reliability?

Railway systems demand extreme reliability. From braking and suspension to door control and maintenance machinery, every component must operate safely under high loads, vibration, and harsh environmental conditions. Among these critical com···

2026-01-15

How Are Hydraulic Cylinders Used in Metallurgical Electric Furnaces?

Metallurgical electric furnaces play a crucial role in modern steelmaking and non-ferrous metal smelting processes. These furnaces operate under extreme conditions, including high temperatures, heavy mechanical loads, and continuous operati···

2026-01-15

How Does Our Hydraulic Cylinder Enhance Metallurgical Electric Furnace Control?

In metallurgical electric furnace systems—such as electric arc furnaces (EAF), submerged arc furnaces, and resistance furnaces—precise mechanical control plays a critical role in ensuring stable operation, energy efficiency, and equipment···

2026-01-08

What Drives Demand for Welded High-Pressure Cylinders?

Welded high-pressure cylinders play a critical role in the storage and transportation of compressed gases across multiple industries. Unlike seamless cylinders, welded cylinders are manufactured by forming and welding steel components, allo···

2026-01-08

How Do We Ensure Durability in High-Pressure Welded Cylinders?

High-pressure welded cylinders are widely used in industries such as energy, chemical processing, medical gases, and industrial manufacturing. Because these cylinders often operate under extreme internal pressure and harsh environments, dur···

GET YOUR FREE QUOTE

We will contact you within 24 hours. ( WhatsApp/facebook:13665121168)