What is the external source of hydraulic power?

Release Time :

2025-02-12

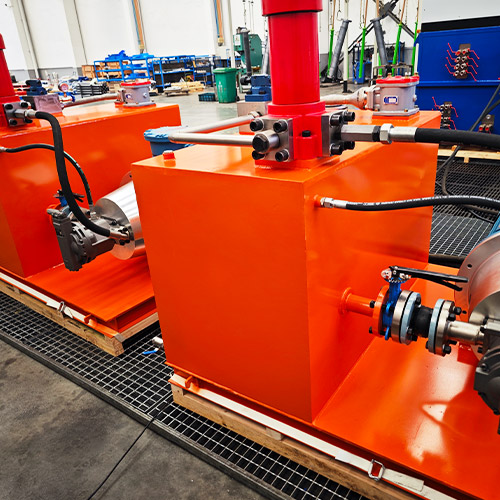

The generic name for an external hydraulic power source is a "hydraulic power unit". It is sometimes also called a hydraulic pump or hydraulic power pack. A hydraulic power unit is a compact assembly that typically includes a hydraulic pump, motor, and oil tank. Hydraulic power is generated by a combination of oil flow and pressure. Oil flow and pressure are generated by the hydraulic pump and transmitted through hoses or pipes and control valves to the hydraulic motor or cylinder that performs the work.

One of the main advantages of hydraulic systems is the ability to transmit large amounts of power from a remote power source (electric motor or internal combustion engine) to a compact actuator.

This power transmission method is fully demonstrated on excavators, where the hydraulic cylinder is mounted on the boom and the diesel engine and pump are mounted behind the cab. All functions can be controlled by the operator in the cab.

A hydraulic power unit combines hydraulic components to supply fluid to the hydraulic system at the required pressure and flow. A hydraulic power unit typically consists of a motor, oil tank, valves, and pump to power the hydraulic system.

There are many options and configurations available for hydraulic power packs, so it is important to understand how to select the correct power pack or assembly. First, determine the required nominal power based on the required flow and pressure, which depends on the force that needs to be applied.

What does a hydraulic power unit consist of?

A hydraulic power unit is a self-contained system that consists primarily of an electric motor, a hydraulic pump, and a reservoir. It converts mechanical energy into hydraulic energy—a combination of flow and pressure used by various machines and equipment. Let’s break down the components that make up these dynamic units:

Motor: This component drives the equipment’s pump.

Hydraulic pump: The heart of the equipment, pumping hydraulic fluid from the tank to the system.

Reservoir: A container that holds hydraulic fluid.

Accumulator: This component stores hydraulic energy for later use or to smooth out pulsations.

Filters: Remove contaminants from the hydraulic fluid to protect the system and ensure efficient operation.

Coolers and heaters: Regulate the temperature of the hydraulic fluid.

Valves: Direct the flow of hydraulic fluid and control system pressure.

How does a hydraulic power unit work?

The function of a hydraulic power unit centers on the principle of hydraulic force. When the motor is activated, it drives the pump, which then pushes hydraulic fluid from the reservoir into the system. This fluid travels through a series of valves and hoses to the hydraulic actuator, which then performs the required work. After delivering energy to the actuator, the fluid circulates back to the reservoir where it is filtered and cooled or heated, and the cycle repeats.

RELATED NEWS

2026-01-22

How Do Hydraulic Cylinders Enhance Railway System Safety?

Railway systems are among the most critical transportation infrastructures worldwide, carrying millions of passengers and vast quantities of freight every day. Ensuring safety, reliability, and operational efficiency is therefore a top prio···

2026-01-22

How Do Our Hydraulic Cylinders Enhance Railway Equipment Reliability?

Railway systems demand extreme reliability. From braking and suspension to door control and maintenance machinery, every component must operate safely under high loads, vibration, and harsh environmental conditions. Among these critical com···

2026-01-15

How Are Hydraulic Cylinders Used in Metallurgical Electric Furnaces?

Metallurgical electric furnaces play a crucial role in modern steelmaking and non-ferrous metal smelting processes. These furnaces operate under extreme conditions, including high temperatures, heavy mechanical loads, and continuous operati···

2026-01-15

How Does Our Hydraulic Cylinder Enhance Metallurgical Electric Furnace Control?

In metallurgical electric furnace systems—such as electric arc furnaces (EAF), submerged arc furnaces, and resistance furnaces—precise mechanical control plays a critical role in ensuring stable operation, energy efficiency, and equipment···

2026-01-08

What Drives Demand for Welded High-Pressure Cylinders?

Welded high-pressure cylinders play a critical role in the storage and transportation of compressed gases across multiple industries. Unlike seamless cylinders, welded cylinders are manufactured by forming and welding steel components, allo···

2026-01-08

How Do We Ensure Durability in High-Pressure Welded Cylinders?

High-pressure welded cylinders are widely used in industries such as energy, chemical processing, medical gases, and industrial manufacturing. Because these cylinders often operate under extreme internal pressure and harsh environments, dur···

GET YOUR FREE QUOTE

We will contact you within 24 hours. ( WhatsApp/facebook:13665121168)