Which type of pump is most commonly used?

Release Time :

2025-02-11

There are many different types of industrial pumps, each designed for a specific use and fluid characteristics. Common types include centrifugal, positive displacement, diaphragm, and submersible pumps.

Centrifugal Pumps

How it works: Centrifugal pumps use an impeller to transfer kinetic energy to a fluid, which is converted to pressure energy as the fluid leaves the pump.

Common Industry Uses:

Water Supply

Wastewater Treatment

Oil and Gas

Chemical Processing

Types of Fluids Pumped:

Water

Oil

Chemicals

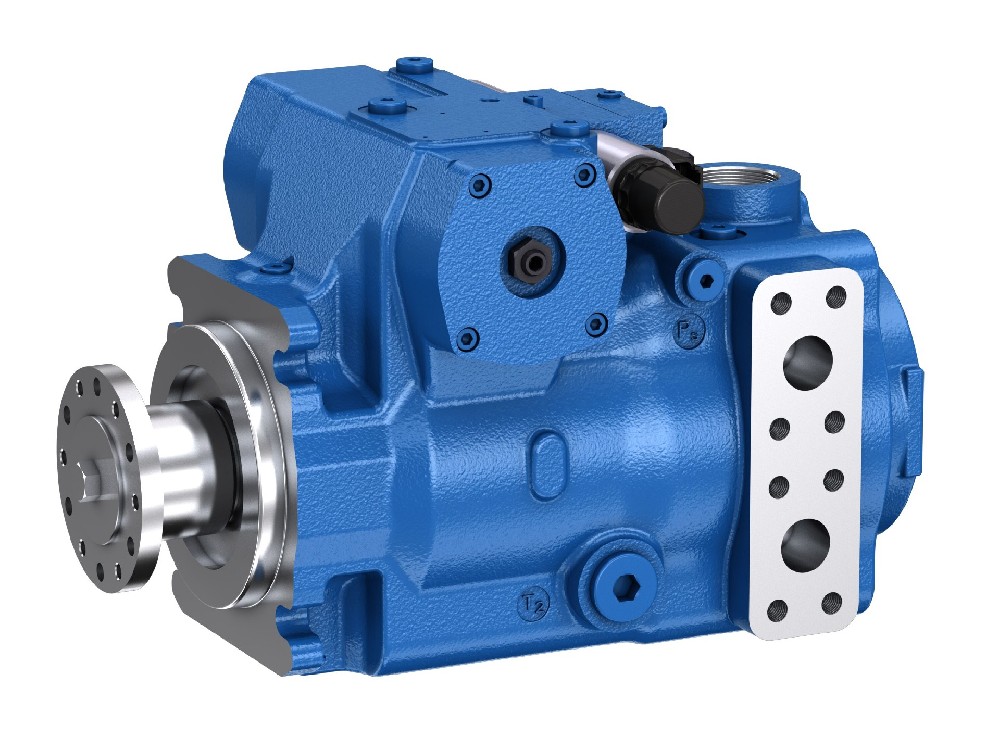

Positive Displacement Pumps

How it works: These pumps move fluids by capturing a fixed amount of fluid and forcing (displacing) it into a discharge pipe.

Common Industry Uses:

Food Processing

Pharmaceutical Manufacturing

Hydraulic Systems

Types of Fluids Pumped:

Viscous Liquids

Slurries

Diaphragm Pumps

How it works: Diaphragm pumps use a diaphragm to move fluids. The diaphragm is pushed and pulled, creating a vacuum that draws in the fluid and then pushes it out.

Common Industry Uses:

Chemical Transfer

Pharmaceutical Manufacturing

Food and Beverage

Types of Fluids Pumped:

Chemicals

Acids

Foods

Gear Pumps

How it works: Gear pumps use gear meshing to pump fluids through displacement.

Functions of Industrial Pumps

Transporting Fluids: The primary function of an industrial pump is to move fluids between locations or processes.

Increasing Fluid Pressure: Pumps are used to increase the pressure of a fluid to move it through a piping system or process equipment.

Circulating Fluids: Pumps are used to circulate fluids in many systems, such as in cooling and heating systems.

Application Areas

Water Treatment: Pumps are used to move water in and out of treatment plants, as well as at various stages of a treatment process.

Chemical Industry: Pumps handle a variety of chemicals, often at high pressure or temperature, or with corrosive or hazardous properties.

Oil and Gas: Pumps are vital in the extraction, transportation, and processing of oil and gas.

Food and Beverage: Pumps are used to handle a variety of liquid ingredients, often with stringent hygiene standards.

Pharmaceuticals: Precision pumps are used to process and manufacture pharmaceuticals.

Agriculture: Pumps are used for irrigation, spraying pesticides, and fertilizing.

Main Features

Capacity and Power: Pumps vary greatly in size and power, depending on the volume and type of fluid they need to handle.

Construction Materials: Pumps are made of materials that are compatible with the fluids they handle, such as stainless steel for corrosive fluids.

Energy efficiency: Modern pumps are designed with a focus on energy efficiency as they are used in a wide range of industries.

RELATED NEWS

2026-01-22

How Do Hydraulic Cylinders Enhance Railway System Safety?

Railway systems are among the most critical transportation infrastructures worldwide, carrying millions of passengers and vast quantities of freight every day. Ensuring safety, reliability, and operational efficiency is therefore a top prio···

2026-01-22

How Do Our Hydraulic Cylinders Enhance Railway Equipment Reliability?

Railway systems demand extreme reliability. From braking and suspension to door control and maintenance machinery, every component must operate safely under high loads, vibration, and harsh environmental conditions. Among these critical com···

2026-01-15

How Are Hydraulic Cylinders Used in Metallurgical Electric Furnaces?

Metallurgical electric furnaces play a crucial role in modern steelmaking and non-ferrous metal smelting processes. These furnaces operate under extreme conditions, including high temperatures, heavy mechanical loads, and continuous operati···

2026-01-15

How Does Our Hydraulic Cylinder Enhance Metallurgical Electric Furnace Control?

In metallurgical electric furnace systems—such as electric arc furnaces (EAF), submerged arc furnaces, and resistance furnaces—precise mechanical control plays a critical role in ensuring stable operation, energy efficiency, and equipment···

2026-01-08

What Drives Demand for Welded High-Pressure Cylinders?

Welded high-pressure cylinders play a critical role in the storage and transportation of compressed gases across multiple industries. Unlike seamless cylinders, welded cylinders are manufactured by forming and welding steel components, allo···

2026-01-08

How Do We Ensure Durability in High-Pressure Welded Cylinders?

High-pressure welded cylinders are widely used in industries such as energy, chemical processing, medical gases, and industrial manufacturing. Because these cylinders often operate under extreme internal pressure and harsh environments, dur···

GET YOUR FREE QUOTE

We will contact you within 24 hours. ( WhatsApp/facebook:13665121168)