How Are Hydraulic Systems Adapted for Different Applications?

Release Time :

2025-12-11

Hydraulic systems are widely used across industries because they offer high power density, precise control, and reliable performance under heavy loads. However, not all hydraulic systems are the same. A hydraulic system designed for construction equipment will be very different from one used in aerospace, manufacturing, or medical devices. To meet the demands of different working environments, hydraulic systems are carefully adapted in terms of design, components, control methods, and safety standards.

In simple terms, hydraulics are flexible by nature—but only if they are engineered correctly for the job.

Understanding the Core of Hydraulic Systems

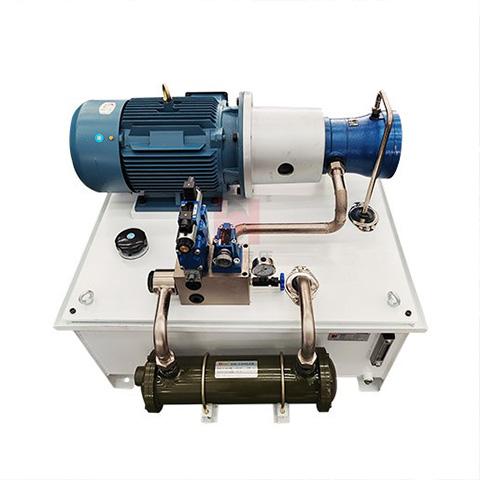

At their core, hydraulic systems transmit power through pressurized fluid, usually hydraulic oil. The basic components include pumps, valves, actuators (cylinders or motors), reservoirs, and control units. While these elements are common across most systems, how they are selected and configured depends heavily on the application.

This is where adaptation comes into play.

Adaptation by Industry Application

1. Construction and Heavy Machinery

Hydraulic systems in construction equipment such as excavators, loaders, and cranes are designed for high power output and durability. These systems must handle extreme loads, dust, vibration, and long operating hours.

Key adaptations include:

High-pressure pumps and reinforced hoses

Large hydraulic cylinders for lifting and digging

Simple, rugged control valves for reliability

Easy maintenance design, because downtime costs money

In plain words, these systems are built tough. They are not pretty, but they get the job done.

2. Industrial Manufacturing and Automation

In factories, hydraulic systems are often used for presses, injection molding machines, and automated production lines. Here, precision and repeatability matter more than brute force.

Typical adaptations include:

Proportional or servo valves for accurate motion control

Integrated sensors for pressure, position, and flow

Compact system layouts to fit into production equipment

Energy-saving designs to reduce operating costs

These systems are smarter and more controlled, even if they don’t look as powerful as construction hydraulics.

3. Aerospace Applications

Aerospace hydraulic systems operate under strict safety, weight, and reliability requirements. They are commonly used in flight control systems, landing gear, and braking systems.

Key design adaptations include:

Lightweight materials such as titanium or aluminum alloys

Redundant system architecture for safety

High-quality seals to perform under extreme temperatures

Strict compliance with aviation standards

In this field, there is no room for shortcuts. Every component must be tested and certified.

4. Mobile and Agricultural Equipment

Agricultural machines and mobile equipment need hydraulic systems that are flexible and easy to operate, often by non-technical users.

Adaptations often include:

Modular valve blocks for multiple functions

Load-sensing systems to improve fuel efficiency

Simple joystick or lever-based controls

Robust designs that tolerate dirt and moisture

These systems are designed to be practical. Farmers don’t want complexity—they want reliability.

5. Medical and Specialized Equipment

In medical devices such as patient lifts or surgical equipment, hydraulics are used for smooth, quiet, and controlled motion.

Special adaptations include:

Low-noise pumps

Precise micro-hydraulic control

Clean, leak-resistant designs

Compliance with medical safety regulations

Here, comfort and safety are just as important as performance.

Control Systems and Technology Adaptation

Modern hydraulic systems are increasingly combined with electronic controls. Depending on the application, systems may use:

Manual control for simplicity

Electro-hydraulic control for precision

Fully integrated PLC or computer-based control systems

This hybrid approach allows hydraulics to remain powerful while becoming more intelligent.

Environmental and Safety Considerations

Different applications also require different approaches to environmental impact and safety:

Biodegradable hydraulic fluids for environmentally sensitive areas

Explosion-proof components in hazardous environments

Pressure relief and fail-safe systems for operator protection

These adaptations are not optional—they are required by regulations and real-world risks.

Conclusion

Hydraulic systems are not one-size-fits-all solutions. Their true strength lies in their adaptability. By adjusting system design, component selection, control methods, and safety features, hydraulic technology can meet the needs of vastly different applications—from heavy construction to delicate medical equipment.

In short, hydraulics work everywhere because engineers make them fit the job, not the other way around.

RELATED NEWS

2026-02-24

Why Is Preventive Maintenance Critical for Hydraulic System Longevity?

Hydraulic systems are widely used in manufacturing equipment, construction machinery, agricultural tools, and industrial automation lines. Because these systems operate under high pressure and continuous load, component wear is inevitable o···

2026-02-24

How Does a Hydraulic System Actually Work?

Hydraulic systems are widely used in industrial machinery, construction equipment, manufacturing lines, and transportation devices. Their core function is to transmit power through pressurized fluid, allowing heavy loads to be moved or cont···

2026-02-17

What Are the Latest Trends in Hydraulic System Design for Paper Machines?

Hydraulic systems play a critical role in modern paper manufacturing by providing stable force transmission, precise motion control, and reliable power delivery. In high-speed production environments, where continuous operation and consiste···

2026-02-17

Why Is My Paper Machine Hydraulic System Overheating?

Overheating in a paper machine hydraulic system is a common operational issue in pulp and paper mills. If oil temperature rises beyond the designed range, it can affect viscosity, component lubrication, sealing performance, and overall syst···

2026-02-10

How Is Eco-Friendly Hydraulic Technology Changing Box Handling?

Hydraulic systems play a central role in automated box handling across logistics centers, manufacturing plants, and distribution warehouses. As operational standards continue to rise, equipment manufacturers are refining hydraulic technolog···

2026-02-10

How to Maintain a Clean Hydraulic System for Moving Boxes?

Hydraulic systems are widely used in box-moving equipment such as lift tables, stackers, conveyors, and automated handling lines. Stable pressure output and smooth actuator movement depend heavily on oil cleanliness and proper system mainte···

GET YOUR FREE QUOTE

We will contact you within 24 hours. ( WhatsApp/facebook:13665121168)