What Makes Our Hydraulic Systems Suitable for Heavy-Duty Use?

Release Time :

2025-12-11

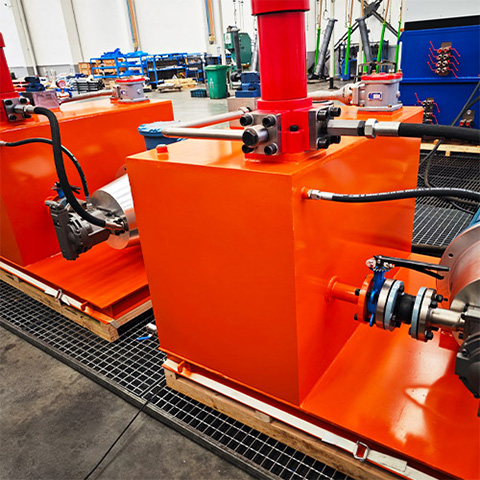

Hydraulic systems are widely used in industries where strength, reliability, and control are critical. From construction machinery and mining equipment to industrial manufacturing and material handling, heavy-duty applications place high demands on hydraulic components. But what exactly makes a hydraulic system suitable for this kind of work?

1. Designed to Handle High Loads Consistently

Heavy-duty operations often involve continuous lifting, pushing, or pressing under high pressure. Hydraulic systems intended for these conditions are engineered to operate within stable pressure ranges while maintaining smooth motion.

Key factors include:

Properly rated pumps, cylinders, and valves

Materials selected for strength and fatigue resistance

System layouts that minimize unnecessary pressure loss

In simple terms, the system is built to do hard work repeatedly, not just once in a while.

2. Durable Materials for Demanding Environments

Heavy-duty equipment is rarely used in clean or mild conditions. Dust, vibration, temperature changes, and long operating hours are common. For this reason, hydraulic systems rely on components made from materials that can withstand wear and environmental stress.

Examples include:

Hardened steel or alloy components for critical parts

Seals designed to resist oil degradation and temperature variation

Protective coatings to reduce corrosion risk

These choices don’t make the system indestructible, but they help extend service life under real working conditions.

3. Stable Performance Under Continuous Operation

Unlike light-duty systems that run intermittently, heavy-duty hydraulic systems are often expected to operate for long periods. Stability becomes more important than peak performance.

A well-designed system focuses on:

Controlled heat generation and dissipation

Reliable oil flow under varying loads

Predictable response from valves and actuators

In other words, it’s not about being flashy—it’s about doing the same job, the same way, hour after hour.

4. Ease of Maintenance and Inspection

In industrial and construction settings, downtime matters. Hydraulic systems suited for heavy-duty use are typically designed with maintenance in mind.

This may include:

Standardized components that are easier to replace

Clear access points for inspection and servicing

Compatibility with commonly available hydraulic fluids

From a practical standpoint, a system that can be maintained efficiently is often more valuable than one that is technically complex but hard to service.

5. Adaptability to Different Applications

Heavy-duty does not mean one-size-fits-all. Hydraulic systems are often customized or configured to match specific equipment and operating requirements.

This adaptability can involve:

Adjustable pressure and flow settings

Modular system design

Compatibility with different control methods

Simply put, the system can be tuned to match the job instead of forcing the job to match the system.

Conclusion

Hydraulic systems suitable for heavy-duty use are not defined by marketing claims, but by solid engineering, material selection, and practical design choices. Their value lies in reliability, durability, and consistent performance under demanding conditions.

At the end of the day, a good heavy-duty hydraulic system is one that works when it’s supposed to, handles stress without drama, and doesn’t create unnecessary problems for operators or maintenance teams. That’s not a bold promise—it’s just good engineering.

RELATED NEWS

2026-02-24

Why Is Preventive Maintenance Critical for Hydraulic System Longevity?

Hydraulic systems are widely used in manufacturing equipment, construction machinery, agricultural tools, and industrial automation lines. Because these systems operate under high pressure and continuous load, component wear is inevitable o···

2026-02-24

How Does a Hydraulic System Actually Work?

Hydraulic systems are widely used in industrial machinery, construction equipment, manufacturing lines, and transportation devices. Their core function is to transmit power through pressurized fluid, allowing heavy loads to be moved or cont···

2026-02-17

What Are the Latest Trends in Hydraulic System Design for Paper Machines?

Hydraulic systems play a critical role in modern paper manufacturing by providing stable force transmission, precise motion control, and reliable power delivery. In high-speed production environments, where continuous operation and consiste···

2026-02-17

Why Is My Paper Machine Hydraulic System Overheating?

Overheating in a paper machine hydraulic system is a common operational issue in pulp and paper mills. If oil temperature rises beyond the designed range, it can affect viscosity, component lubrication, sealing performance, and overall syst···

2026-02-10

How Is Eco-Friendly Hydraulic Technology Changing Box Handling?

Hydraulic systems play a central role in automated box handling across logistics centers, manufacturing plants, and distribution warehouses. As operational standards continue to rise, equipment manufacturers are refining hydraulic technolog···

2026-02-10

How to Maintain a Clean Hydraulic System for Moving Boxes?

Hydraulic systems are widely used in box-moving equipment such as lift tables, stackers, conveyors, and automated handling lines. Stable pressure output and smooth actuator movement depend heavily on oil cleanliness and proper system mainte···

GET YOUR FREE QUOTE

We will contact you within 24 hours. ( WhatsApp/facebook:13665121168)