What Role Do Hydraulic Systems Play in Automation?

Release Time :

2026-01-01

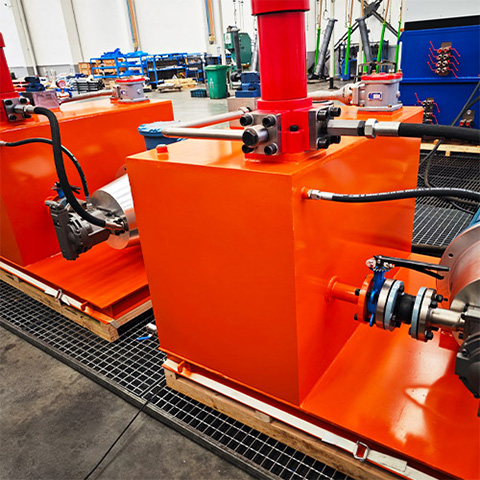

Automation has become a key driver of efficiency and consistency in modern industry. From manufacturing and material handling to construction and energy sectors, automated systems are designed to reduce manual intervention while improving accuracy and productivity. In this context, hydraulic systems continue to play an important and sometimes underestimated role.

Although electric and pneumatic systems are widely used, hydraulics remain essential where high force, precise control, and durability are required. So, what exactly do hydraulic systems contribute to automation? Let’s look at it in a practical and realistic way.

1. Providing High Power Density for Automated Motion

One of the main strengths of hydraulic systems is their high power density. Compared with electric or pneumatic solutions, hydraulics can generate much higher force from relatively compact components.

In automated equipment, this makes hydraulic systems suitable for:

Pressing and forming operations

Lifting and positioning heavy loads

Clamping and holding workpieces securely

In simple terms, when automation needs serious muscle in a limited space, hydraulics are often the logical choice.

2. Enabling Precise and Repeatable Control

Modern automation is not just about movement; it’s about controlled and repeatable movement. With advancements in hydraulic technology, systems can now achieve high levels of accuracy through:

Proportional and servo valves

Closed-loop control with sensors

Integration with PLC and industrial control systems

This allows hydraulic actuators to perform smooth, controlled motions that are repeatable over long operating cycles. The result is stable process quality—something automation depends on heavily.

3. Supporting Automation in Harsh Environments

Automated systems are often deployed in environments that are far from ideal, such as:

High temperatures

Dusty or wet conditions

Outdoor or underground locations

Hydraulic systems are well suited to these conditions due to their robust construction and tolerance to environmental stress. While they still require proper maintenance, hydraulics generally handle tough conditions better than many purely electric solutions. Simply put, they are built to take a beating and keep going.

4. Integrating with Electronic Control and Smart Systems

Hydraulics are no longer “standalone” mechanical systems. In automation, they are commonly integrated with electronic controls to form electro-hydraulic systems.

Typical integration includes:

Sensors for position, pressure, and flow

Electronic controllers for real-time adjustments

Communication with centralized automation platforms

This combination allows hydraulic systems to respond dynamically to process changes, making them an active part of intelligent automation rather than a passive power source.

5. Improving Safety in Automated Operations

Safety is a core concern in automation, especially where high forces are involved. Hydraulic systems can contribute to safer automated processes by:

Providing stable load holding without continuous energy input

Enabling controlled emergency stops

Supporting fail-safe designs through pressure control and locking mechanisms

These features help reduce the risk of sudden movements or uncontrolled load drops, which is critical in automated environments.

6. Enhancing Efficiency in Specific Automated Applications

While hydraulic systems are not the best solution for every automated task, they excel in applications where:

Force requirements are high

Motion needs to be smooth and controlled

Equipment operates in continuous or heavy-duty cycles

By choosing hydraulics where they make sense—and not forcing them where they don’t—automation designers can achieve a balanced and efficient system. This kind of flexibility is often what makes an automation project successful.

7. Adapting to Evolving Automation Needs

Hydraulic systems also offer a degree of adaptability. With proper design, they can be upgraded through:

Improved control valves

Digital sensors

More efficient pumps or power units

This allows existing automated equipment to evolve alongside new control technologies without complete system replacement. It’s a practical approach that many industries appreciate.

Conclusion

Hydraulic systems play a vital role in automation by delivering high force, precise control, durability, and reliability where it matters most. Through integration with electronic controls and smart monitoring, hydraulics have adapted well to modern automated environments.

They are not a universal solution, but when applied thoughtfully, hydraulic systems remain a powerful and flexible tool in automation. In short, they quietly do the heavy work behind the scenes—and automation wouldn’t be the same without them.

RELATED NEWS

2026-02-24

Why Is Preventive Maintenance Critical for Hydraulic System Longevity?

Hydraulic systems are widely used in manufacturing equipment, construction machinery, agricultural tools, and industrial automation lines. Because these systems operate under high pressure and continuous load, component wear is inevitable o···

2026-02-24

How Does a Hydraulic System Actually Work?

Hydraulic systems are widely used in industrial machinery, construction equipment, manufacturing lines, and transportation devices. Their core function is to transmit power through pressurized fluid, allowing heavy loads to be moved or cont···

2026-02-17

What Are the Latest Trends in Hydraulic System Design for Paper Machines?

Hydraulic systems play a critical role in modern paper manufacturing by providing stable force transmission, precise motion control, and reliable power delivery. In high-speed production environments, where continuous operation and consiste···

2026-02-17

Why Is My Paper Machine Hydraulic System Overheating?

Overheating in a paper machine hydraulic system is a common operational issue in pulp and paper mills. If oil temperature rises beyond the designed range, it can affect viscosity, component lubrication, sealing performance, and overall syst···

2026-02-10

How Is Eco-Friendly Hydraulic Technology Changing Box Handling?

Hydraulic systems play a central role in automated box handling across logistics centers, manufacturing plants, and distribution warehouses. As operational standards continue to rise, equipment manufacturers are refining hydraulic technolog···

2026-02-10

How to Maintain a Clean Hydraulic System for Moving Boxes?

Hydraulic systems are widely used in box-moving equipment such as lift tables, stackers, conveyors, and automated handling lines. Stable pressure output and smooth actuator movement depend heavily on oil cleanliness and proper system mainte···

GET YOUR FREE QUOTE

We will contact you within 24 hours. ( WhatsApp/facebook:13665121168)